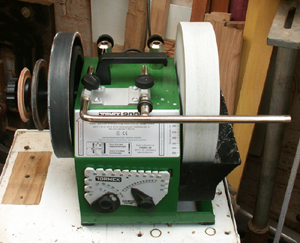

This is one of my best buys.

Initially I would not look at this machine, thinking it was overpriced, and whilst I am relatively new to woodturning, I have been using grinders all my working life, and I was convinced my tools were as sharp as you could get them. NOT SO !.

I received a free DVD with a woodturning magazine and I did not even bother looking at it, then a friend of mine asked if I had watched it, and a rainy day prompted me to do just that. I subsequently purchased one and it certainly lives up to the reputation that follows its name.

I get a better finish straight from the tools, therefore do not have so much sanding to do. The tools remain sharper longer. What a fool I was not to buy one sooner. If you have not seen the DVD look on their website http://www.tormek.com.